- biuro@resic.pl

- +48 501 816 090

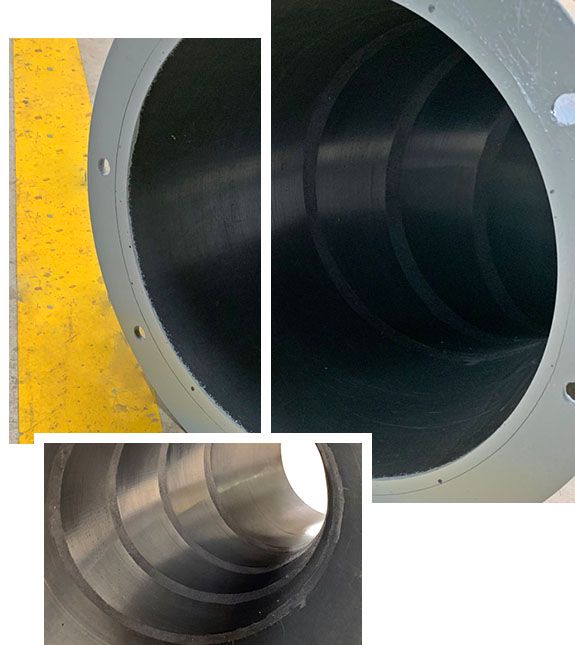

A composite material based on silicon carbide and hybrid resins.

RESIC is designed for protection and renovation of elements exposed to extreme friction and wear by solid particles, corrosion, acids and bases.

RESIC composite allows to create lining of any geometry, according to the client's order, and the extraordinary strength of RESIC lining allows to eliminate steel from the process line.

Machines and processing facilitates operated in the energy, chemicals, mining, paper and petrochemical industries or in the area of mechanical processing are particularly exposed to factors activating chemical, abrasive and corrosive processes that lead to degradation of the material. That is why it is so important to take into account the temporal material resistance to the medium affecting it in advance, at the stage of the system design - our RESIC composite makes it possible.

Silicon carbide, which is characterized by a high hardness of up to 9.5 on the Mohs scale, which is the main component, makes the material very hard. Mechanical resistance to abrasion and corrosion makes RESIC a perfect

material for industries that involve harsh working conditions. This composite has a high coefficient of thermal conductivity and is resistant to sudden changes in temperature.

The use of our composite technology in difficult conditions provides four times longer working time than rubber or

polyurethane materials. Excellent adhesion ensures reliability and prevents tearing off layers. It withstands chemically changing working conditions. The agent can be easily applied to various types of surfaces.

Max. operating temperature up to 160°C

Max. short-time operating temp. up to 200°C

Composite density 2,40 g/cm 3

Color: graphite

The use of RESIC allows for 8 thousand working hours.

For comparison, rubber or polyurethane lining works in the same conditions abaut 1 thousand hours.

Wherever a pump is exposed to severe operating conditions due to both technically and chemically aggressive medium used. For example, flotation pumps or pumps working with material from a desulphurisation system. RESIC lining is resistant to solid particles found in liquids and aggressive suspensions in many areas of application.

We renovate pumps, among others, of the following brands:

Lining of hydrocyclones, cyclones and their components - spare parts.

Production of lining for HC-500/20 ZAM-IMN hydrocyclones and HC-350/20 ZAM-IMN hydrocyclone.

RESIC lining includes both hydrocyclone head and cones lining as well as the production of full carbide inlet and outlet cyclone nozzles and overflow elements.

We renovate and manufacture spare parts for, among others, hydrocyclones of the following brands:

Hydro transmission systems and systems for pneumatic transport and mechanical transport.

Wear-resistant lining of pipes, straight connection pipes, elbows and fittings of the transport installation.

See below the gallery of the projects we have completed for our clients

If you have any questions about our products, please call or e-mail us.

Our company has many years of experience in the production of technological installation elements made of plastics.

We produce precise small parts of installation systems as well as large-size structures.

RESIC means comprehensive support of investments and innovative implementations for the mining, energy, chemical and civil engineering industries.